- -15%

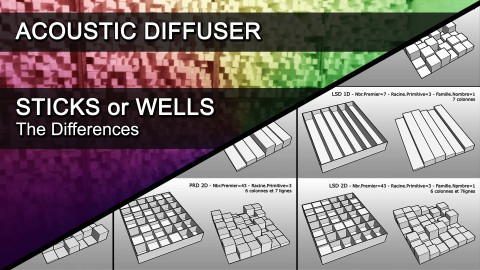

equivalent to a cost price of 27.50 € per diffuser

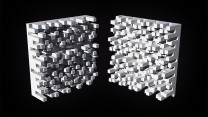

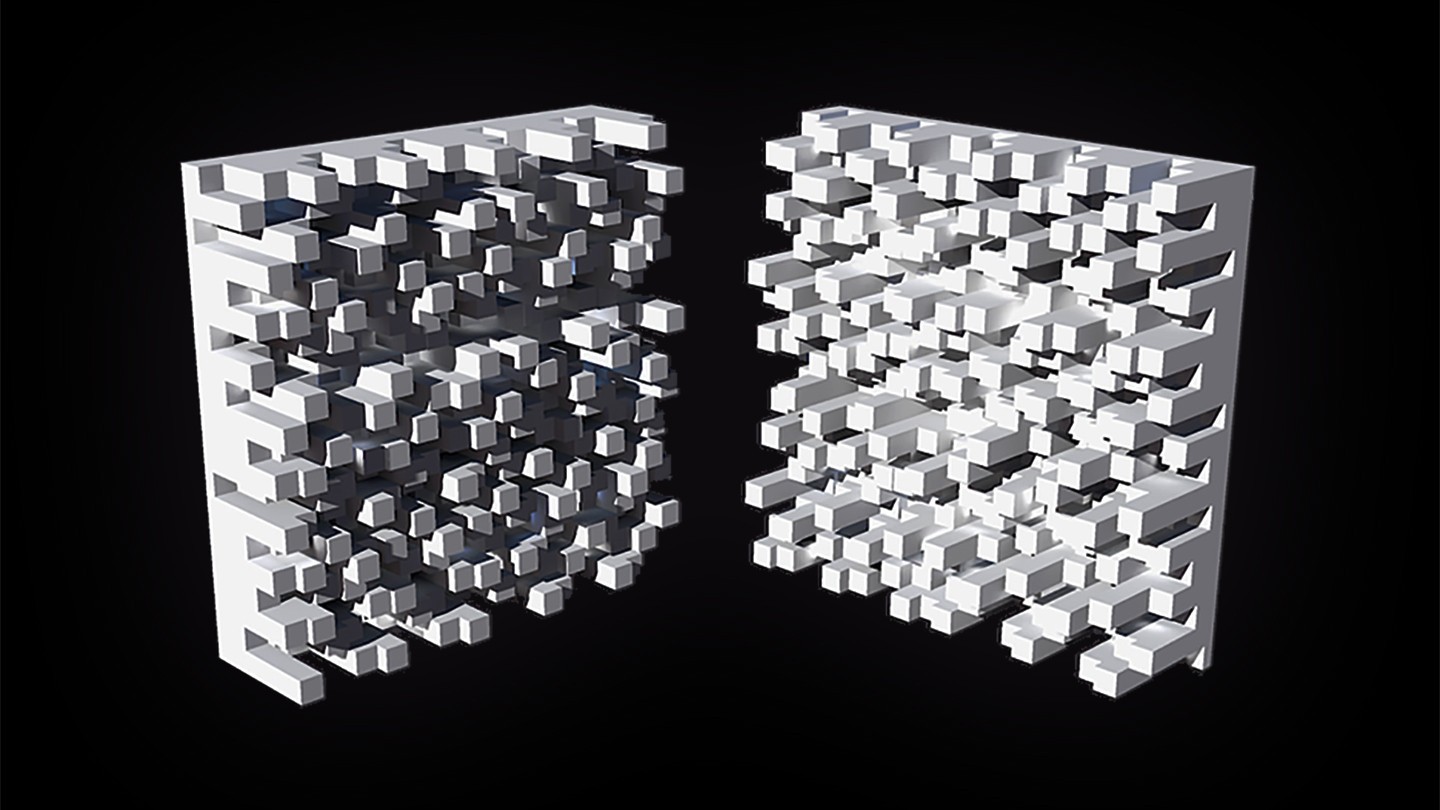

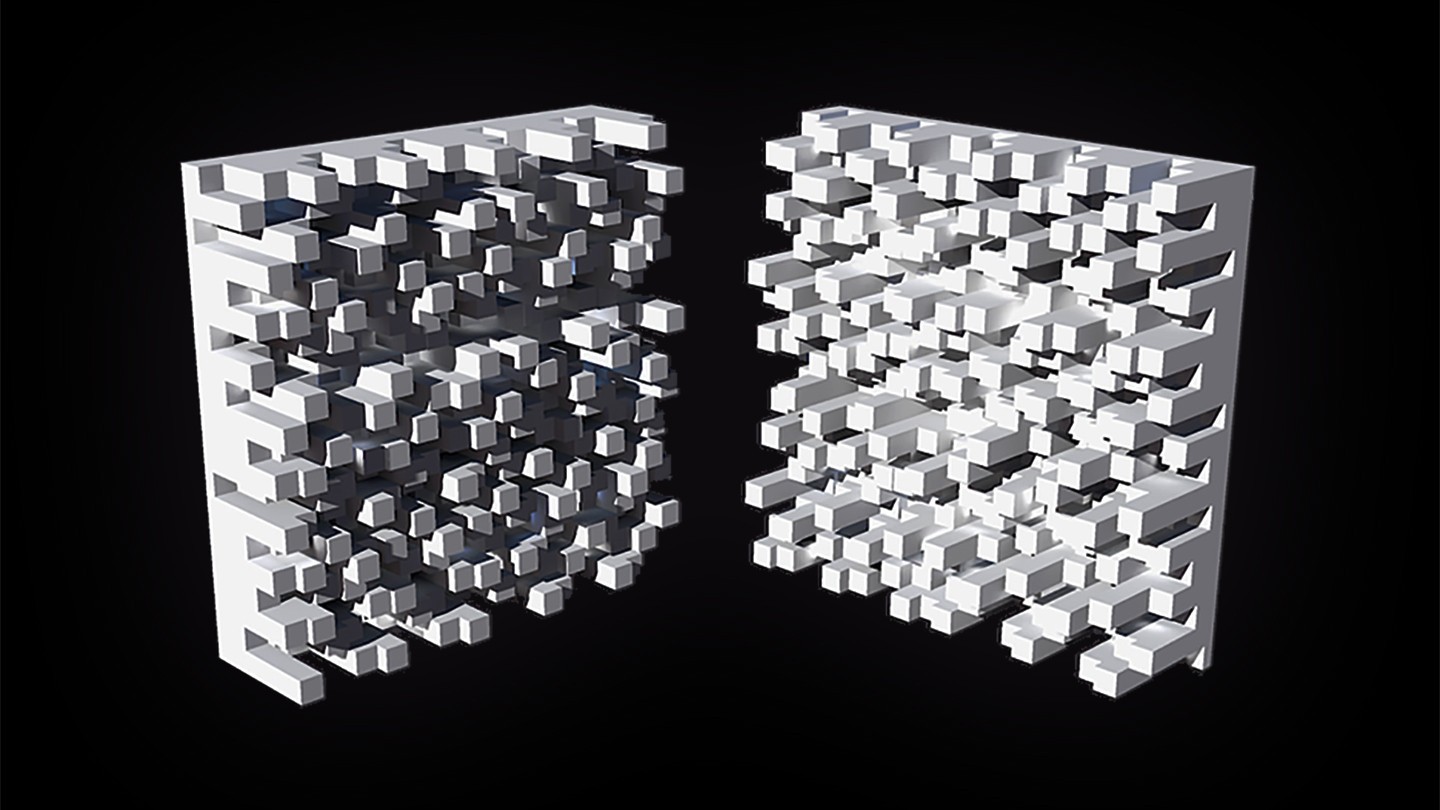

Pair of acoustic diffusers consisting of one type A diffuser and its inverse type B. These two types are mutually mirrored with respect to each other, in order to avoid problematic phase correlations that occur when two identical elements are placed in proximity.

Each diffuser is composed of 20 pre-cut lines, to be assembled by placing them next to each other.

Three years of research were necessary to develop this revolutionary diffuser in terms of its efficiency and price. Nothing was left to chance in its design. Comprised of 400 "pseudo cells" on a stick in just 60cm², this French-designed and manufactured diffuser offers remarkable diffusion and dispersion properties, making it an essential reference.

Inspired by the QRD (quadratic residues) model, the PRD (primitive root) model, and the improved models LSD (Lüke sequence) and PWRD (power residue), the MDD (Mac Door Diffuser) sequence brings together the best of the most renowned sequences based on prime numbers to merge into a new formula patented in 2019, designed and optimized for stick diffuser designs.

This revolutionary sequence has the following characteristics:

Technical specification

You might also like

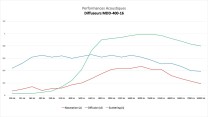

3 years of research, over 6,000 hours of study, experimentation, questioning of what has already been done in terms of diffusion, and the creation of about sixty diffuser devices made with different materials and sequences in order to understand, find, and achieve the best acoustic diffusers, have led me to develop my own method for simulating the behavior of a diffuser, a demonstration method based on observing a 'ripple tank,' a serious questioning of the certainties we had about their behaviors, and finally, my own distribution method, which varies depending on whether the diffuser design is based on rods or wells.

When it comes to diffusers, "experts" generally agree on a preference for well-based designs over stick-based ones. However, my investigations have led me to the conclusion that, depending on the sequence type and implementation constraints, stick-based designs often yield better results when the number of cells is substantial. After selecting the diffusers (generated randomly using the "Mersenne Twister") that exhibit superior characteristics to QRD, PRD, LSD, and PWRD models, in line with the predictions of my analyzer using the "brute force" method, I set out to examine the similarities in their designs to identify the elements necessary for optimal diffusion.

Ces diffuseurs sont devenus une référence dans le traitement acoustique ! Ils sont faciles à assembler et sont bien plus efficaces (plus grosse plage de diffusion) que ceux disponibles sur Thomann par exemple. Bref, je recommande !

Super produit à monter soi meme mais rapport qualité prix imbattable !

J’ai commandé 14 paires de diffuseurs MDD400 pour finaliser le traitement acoustique de mon studio de 9 m². 7 paires installées au plafond, 2 paires pour les côtés, 2 paires pour la face avant et 3 paires à l’arrière. Résultats mesurés : - Lissage du RT60 sur une bande fréquentielle bien plus large que prévu - Meilleur contrôle de la réponse en fréquence dans les médiums et haut-médiums Résultats perçu : - Précision d’écoute nettement supérieure avec mes KH310 + KH750 : scène stéréo élargie, son plus détaillé même à fort volume - Fatigue auditive réduite, comparé à la période où seul un traitement absorbant était présent Service : Andy a été très réactif à chacun de mes messages pour m’aider à mener ce projet à bien. À la réception des colis, deux lames avaient subi des dommages : Andy m’a immédiatement proposé un remplacement.

Les meilleurs diffuseurs du monde.Bravo et Merci Andy.En plus franchement ils sont beaux , enfin c’est mon avis je trouve que ça en jette…. Les mesures avec REW avant et après la pose de 14 diffuseurs dans mon home studio de 10m2 ,le montrent bien. Si vous hésitez encore ,ne réfléchissez plus, foncez.

Mon usage est pour l'écoute Hi-Fi type DIY Baffles Plans dans une petite pièce de 16 m². Après tests de positionnement, sur les mur de la première réflexion de chaque canal j'ai mis un diffuseur au niveau du large bande. Au centre à 40 cm de la fenêtre un peu plus haut que les Baffles plans 1 diffuseur. J'ai une voie grave (100 x 60 x 50) avec 2 x 38cm où j'ai posé un diffuseur orienté vers le plafond et enfin à 50 cm derrière moi contre le mur 2 diffuseurs réunis. J'obtiens une image large, profonde et douce. La précision de la scène sonore et incroyable et toute la sensiblité des interprètes (voix et instrument) est remarquable. Le système "disparait" en fermant les yeux on a l'illusion de présence la taille de pièce disparait. J'en suis très content. J'ai converti 2 amis audiophiles qui on de beaux système. Pour assembler à 2 la dernière commande de 6 diffuseurs nous avons 1h30. Je recommande sans réserves

Très bon produit. Très facile à poser. Amélioration très perceptible sur la qualité sonore. Je l’ai placé au plafond dans mon installation hi-fi. Très bon rapport qualité prix. Je recommande.

Reçu rapidement en point relais, prix compétitifs et le montage est simple puisque chaque ligne du diffuseur est préalablement repéré (veiller à respecter le sens du montage)chaque diffuseur a son contraire en plage de diffusion (A et B)pour ma part je les ai peint en noir mat et installés dans une salle home cinéma dédiée au début je n'ai pas réellement entendu de différence mais mes enceintes étaient encore en période de rodage et récemment je me suis aperçu qu'il y avait bien une différence le son transmis est plus clair et précis, bravo .

J'ai monté 6 paires de diffuseurs dans mon studio, très impressionné par l'efficacité surtout de ceux au plafond, ça change vraiment l'acoustique de la pièce. En complément Andy m'a donné des conseils pendant une longue conversation au téléphone, ce qui m'a permis d'avancer au mieux ! Super pro :)

Very happy with these. I installed a matrix of 4x5 on my mixing ceiling. Light like a feather, so I am very happy with them, what a difference in installing this compared to the wooden ones. Great work!

Juste incroyable, en tant qu'Audiophile ces diffuseurs ont fait la plus grandes différences dans mon système et de très loin, je vais même vendre la plupart de mon matériel ultra cher pour juste en acheter plus

Livraison très rapide, facile à installer, produit de qualité ;) pour deux panneaux, j'ai utilisé 1 seul tube de colle le produit est élégant et met une touche pro à mon home studio!

“Diffuseurs bien conçus et efficaces. L’installation est simple et le rendu acoustique se fait rapidement sentir : meilleure ouverture de la scène sonore et une impression d’espace accrue. La finition est propre et sérieuse, le rapport qualité/prix est excellent. Très bon produit que je recommande sans hésiter.” Merci pour votre professionnalisme et efficacité. Et ingéniosité ?

Très bon rapport qualité prix, je recommande vivement

Pas la première séries de panneaux que je prend et toujours aussi bien réalisé. Excellent travail d'andy ?

Les panneaux d'andy macdoor sont excellent sur leur aspect de gestion acoustique et d'une simplicité de montage en plus. On ne peut que recommander ce genre de panneaux au vue de ce qu'il existe sur le marché nous sommes là dans le rapport qualité prix indetronable avec en plus la cerise de voir que la gestion d'onde de ces panneaux s'en retrouve au dessus des panneaux existant ailleurs, et je dis ça travaillant moi même avec tout les fabricants de panneaux existant.... Merci.

Excellent produit, facile à monter, la qualité du son est au rendez-vous ! Je recommande.

Après de nombreuses recherches et travaux acoustique dans ma pièce,je me suis intéressé aux travaux de andy mac door et ses produits. Le diffuseur MDD-400-16 est une référence de produit qualité/prix /performance . Je me demande même pourquoi le prix est aussi bas vu les performances du produits. J ai installé 6 diffuseurs au dessus de moi et le gap audiophile est dessuite ressenti . Des basses propres et homogène, des médiums mis en avant et claire,des aigus limpides transparent. Ma pièce de 25 m2 est devenu une salle amphithéâtre avec son immersif . Merci ,je ne regrette pas et vivement la prochaine commande . Produit d excellence !!!

J'avais identifié ces diffuseurs MDD-400 depuis un moment. Finalement j'en ai commandé 10 paires. La performance est au RDV, le prix est correcte. Absolument infaisable en bois sans prendre deux siècles et 5x le prix. Les diffuseurs sont performants, légers, facile à fixer au sol ou sur les murs. Attention uniquement colle sans solvant type acrylique. Vraiment de bons produits. Si vous voulez quelques chose de pro dans votre studio (voir home studio) ou control room c'est l'outil idéal. Merci Andy qui m'a donné de précieux conseils. Musicalement !

j'ai commandé 4 diffuseurs. J'ai une double contrainte dans mon studio car il sert à la fois de local de répet et de home studio. Je suis donc obligé d'utiliser ma pièce sur un tiers (Nord est) de la pièce pour laisser la place aux musiciens et instruments, et ce n'est pas le meilleure situation (il faudrait que le home studio soit au milieu de la pièce). J'avais corrigé avec des bass trap "maison" et des mini résonateurs (vu sur tuto de Andy) qui m'ont corrigé mes problèmes persistants de basses fréquence mais la perception du son et le confort d'écoute étaient "bizzare" (peut être un effet de peigne). Les 4 diffuseurs ont grandement apporté à mon confort d'écoute, et même s'il demeure des imperfections acoustiques dans mon local, j'ai pu isoler pas mal de problèmes et donc mieux maîtriser l'ensemble du spectre sonore. Les diffuseurs d'Andy ont largement contribué à cette embellie et j'ai bien ressenti le avant et le après. La livraison a été rapide et le produit conforme. Le montage et le collage se sont parfaitement passés avec les tutos d'Andy. Vu les prix des diffuseurs du marché, je peux vous assurer que les MDD 400 16 sont d’un excellent rapport qualité/prix. Leur conception et leur efficacité les placent largement au-dessus de certaines solutions bien plus coûteuses.

The first batch of diffusers has been purchased and I am writing this review on that basis , a new batch is currently in the planning stages. When you have been professionally involved in music production for 30 years and are constantly in a studio environment diffusion is not a foreign concept to you , nor are absorption and reflection. Then you have a lot of experience and all the knowledge literally at the tip of your finger , but it still takes some time to get acquainted with a new product. I came across Andy's diffusers quite by accident , literally by accident. And I am very happy about that. Primarily because of their light weight , I was looking for something like that. They are not difficult to assemble , but it takes a little skill to do so. EPS is a very grateful material , but you have to have a light hand when handling them because every time you press harder , the material shows. These diffusers do a great job , you can't go overboard even if you place 100 of them in a room. Of course , it is ideal to have an even ratio of diffusion and absorption , and constant measurement of the acoustics of the room will tell you the best. My last project in which I used these diffusers is the so-called room within a room where the outer surface is 36 square meters and the inner surface is 25 square meters. I tested the diffusers in all locations , on the wall behind the speakers and behind the listening position , on the first side reflections , as well as on the counter-carpet position. The effects are clearly expressed in all positions , now it is up to each user to choose the ratios with absorption. My idea is to make the space as lively as possible with absolute control of all the first and later reflections. In short , the diffuser is for every recommendation , the ratio of money invested and the result obtained is extremely good.

Expédié rapidement. Le montage est très facile grâce aux numéros. Le rapport qualité prix est très bon quand on voit les prix pratiqués par les autres fabricants. Je ne pouvais pas installer des diffuseurs en bois ( trop lourd), ces diffuseurs sont très légers , je les ai collé sur des panneaux de polystyrène extrudé avec un système d'attache qui me permet de les retirer facilement des murs si nécessaire. Je ne suis pas encore passé à la peinture mais cela ne va pas tarder. Au niveau efficacité, il y a du positif, difficilement quantifiable car je refais l'ensemble de l'acoustique de ma salle dédiée hc et donc il y a d'autres changements ( panneaux absorbants , panneaux hybrides ... que j'ai rajouté)qui ont dû influer le rendu mais dans l'ensemble ces panneaux font le job. Donc satisfait de ma commande qui ne sera peut-être pas la dernière.

Je suis très satisfait du produit . Le son de mon studio a carrément changer dans le positif. Je tiens à remercier Andy car il y a quelques Mois j’avais des questions et il m’a carrément téléphoné et nous sommes rester une heure au téléphone avec des réponses claire d’ordre général en home studio . Je recommande Andy .

Achetés en août 2024, je viens finalement de sortir les diffuseurs du carton et les installer dans mon nouveau studio, Ça marche très bien et ça compense le côté très absorbant du traitement acoustique que j'ai fait. Je crois même que je vais en rajouter quelques uns pour accentuer la spatialisation. En tous cas merci à Andy pour son travail impressionnant et ses tarifs abordables. Serge Houppin

Ayant comme projet de traiter le plafond de mon salon ou se trouve le système hi-fi, j'ai contacté Andy du coup, merci d'ailleurs à lui pour sa franchement belle joie de vivre et très sympathique mais aussi très compétent, il prend vraiment le temps de vous conseiller sur le questionnement que vous pourriez avoir. Je lui ai acheté 6 diffuseurs acoustique MDD- 400-16 et placés selon les recommandations d' Andy et wahouuuuuu, quelles différences le avant/après avoir traiter le plafond avec ses diffuseurs !! Je conseille vraiment au gens qui sont hésitant (c'était mon cas) de franchir ce cap du traitement acoustique de sa pièce, changement bien plus important qu'un changement de câble secteur, usb, etc etc. Satisfait donc à 200%, encore un grand merci à Andy pour sa patience et ses conseils qui font "mouche", foncer, vous ne le regretterai pas.

Interrogatif au départ sur la pertinence de tels objets, je peux confirmer maintenant l'intérêt de mettre au moins quelques uns de ces diffuseurs reparti sur les emplacements de réflection des HP dans une pièce de vie. Je ne peux pas dire que l'objet soit joli, mais il semble faire le taff. J'ai constaté une amélioration acoustique de ma pièce avec un son plus précis... Je précise que je suis en hifi domestique et non studio d'enregistrement.

j'utilise ces diffuseurs depuis longtemps, efficacité remarquable, rapport qualité prix imbattable. le soucis c'est de bien choisir la colle. bien la laisser sécher surtout pour une utilisation au plafond. la structure fermé du polymère n'aide pas au séchage.

Voilà quelqu’un qui prend son temps pour vous expliquer, vous conseiller… et, visiblement, il connaît son boulot et sait de quoi il parle. Quant à ses diffuseurs, ils sont arrivés très bien emballés et la fabrication et l’expédition ont été très rapides. L’assemblage est très facile à faire, même pour quelqu’un qui a deux mains gauches. La fixation est un peu plus délicate. Le prix de vente est plus que correct. On ne trouve rien qui fonctionne à ce prix, et même, bien au-dessus. Après l’installation, les changements dans l’écoute sont radicaux et très perceptibles. Avec six paires placées au plafond (Andy m’a conseillé de faire et placer des absorbeurs également au plafond), l’écoute est, d’emblée, beaucoup plus naturelle, plus large, plus profonde, plus précise. On se rapproche réellement d’une écoute en live. Un grand merci Andy.

Difficile de se plaindre : le prix est imbattable, l'efficacité est audible et mesurable ! Alors oui, il faut bricoler un poil pour les accrocher, les coller, etc,... mais les tuto vidéo à dispo expliquent ça très bien, et pour le prix je reste 100% satisfait. Il a sûrement mieux encore mieux, mais ce n'est pas du tout le même prix ! Sachant qu'à moins de 30e le panneau, Andy répond quand même avec plaisir et précision aux questions, pour nous aider à faire le meilleur choix et tirer le meilleur parti de ses diffuseurs. Merci encore !

Très facile à fabriquer , Légèreté du diffuseur, et rapports qualité efficacité prix super. Merci.

J'ai reçu ces MDD-400 il y a quelques temps et j'ai senti immédiatement la différence. Vraiment agréable à l'écoute, ma stéréo s'est bien améliorée. Je recommande vraiment après avoir longuement étudier les produits que j'allais prendre. Clairement, je pense que ceux-là sont vraiment les meilleurs !! C'est très simple à monter mais je conseille de prendre son temps car le matériau reste fragile et il faut bien être concentrer pour le bon suivi des numéros. J'en acheté 2 paires mais je pense que j'en reprendrais !! J'ai trouvé un système pour le coller au mur bien plus simple que de la colle et instantané !!

Conforme à ça que j'attendais et vraiment efficace. Le montage est un peu fastidieux au début, mais une le coup de main pris, ça devient facile et presque marrant. Je conseille sans réserve !

Après l'installation de six diffuseurs pour l'écoute de ma hifi, je suis très enthousiasmé par ce que cela apporte en terme de spatialité et de présence scénique. 6 autres sont en commande ?

Toujours satisfait des diffuseurs créés par Andy. Il n'y a pas mieux question rapport qualité/prix ! A commander les yeux fermés (et les oreilles bien ouvertes pour apprécier le résultat) ;-))

J'avais déjà un bon détail dans ma petite pièce d'écoute sous mansarde. J'ai posé 3 MDD-40-16 sur la mansarde arrière. Le résultat est très satisfaisant: plus de séparation des voix, plus de détails dans les aigus, plus d'ampleur et dynamique dans le son. Je recommande ce produit à tous les amoureux de l'écoute en HI-FI.

J'ai un home studio de 12 m² en osb. Le son est déjà mat à l'origine. J'ai construit un bass trap pour corriger une fréquence basse qui gênait un peu et mis quelques absorbeurs sur les premiers points de réflexion et en mesurant à chaque fois. À un moment, on sent qu'on n'arrive plus à améliorer l'acoustique. Il reste toujours des petits problèmes. J'ai posé 3 kits de diffuseurs, soit 6 panneaux (3 au plafond et 3 autres sur le mur en face des moniteurs). Pour information, sur l'osb la colle acrylique ne tient pas bien, il y en a un qui est tombé du plafond, et la colle Leroy Merlin en séchant ne s'enlève pas facilement, elle durcit et c'est la galère pour la décoller des panneaux. J'ai utilisé ensuite une néoprène et ça tient. Au niveau des mesures après la pose, j'ai constaté que le RT 60 est légèrement plus plat qu'avant. Il reste encore des petits problèmes de phases, mais ça reste tout à fait correct pour un home studio. À l'oreille, je n'ai pas senti de différence de perception, la pièce est toujours mate. Mon RT 60 montre que mes médiums et aigus sont autour des 250 ms. Si la pièce a un son mat à la base, je ne pense pas qu'on puisse faire grand-chose...Andy m'a conseillé de mettre 6 kits soit le double de ce que j'ai actuellement. Je vais voir ça dans un second temps en posant le reste au plafond afin d'avoir un avis objectif. Cependant, j'hésite, car la pièce est déjà bien encombrée. En utilisant le micro de mesure et le logiciel Sound Id de chez Sonarworks on arrive à un résultat qui est concluant. Le produit est de bonne qualité, je l'ai laissé neutre, c'est bien comme ça. Il est assez joli sur les photos, ça rend bien. Je suis un musicien DIY passionné, je pense être arrivé à un résultat correct pour travailler. Maintenant place à la musique ! Et merci Andy pour toutes tes vidéos, quel travail !

J'ai acheté 12 panneaux et j'ai suivi le tuto d'Andy Mac Door pour le collage : c'est très facile et c'est nickel. Le rapport qualité/prix est imbattable pour un produit très performant, la livraison est rapide. Je recommande vivement ces diffuseurs !

Bonjour, J'en ai acheté 12 et ai maintenant le mur derrière ma position d'écoute entièrement couvert de ces diffuseurs, En ayant suivi les recommandations d'Andy Mac Door (sur YouTube), c'est simple à coller, et ça tient bien. Tôt ou tard, je pense en acheter 6 autres pour en mettre davantage. Je recommande vivement cet article ! -Anthony

Livraison rapide, efficace et facile à assembler Merci

Je n'ai pu en mettre que deux, derrière la zone d'écoute, la pièce étant minuscule, et les diffuseurs ayant une épaisseur non-négligeable, mais j'en suis ravi, les performances sont probablement aussi bonnes qu'avec des diffuseurs en bois (beaucoup plus coûteux), mais sans le poids, donc beaucoup plus facile à installer, et de loin. Peints en gris, pour s'accorder à la couleur des absorbeurs et absorbfusers présent dans la pièce, ils rendent super-bien. Livraison et emballage parfaits. Recommandé à 100%. Juste une petite suggestion : S'il y avait eu une seconde version, certes moins "ambitieuse" au niveau des performances, mais d'une épaisseur plus faible, genre 7-8cm, plus ou moins, j'en aurais pris pour mettre au plafond ;) .

Dans un petit salon d écoute dédié ( 3.5 m X 3.5 m ) , j ai placé 4 panneaux horizontalement derrière le fauteuil a hauteur des oreilles , 4 panneaux derrière les enceintes et 2 aux plafonds . Pour les cotés , j ai fait le choix de " tuer " les ondes réflexives avec des panneaux maisons a base de laine de bois d 'épaisseurs 150 mm. Installation totalement empirique , sans mesure au préalable de la fréquence de résonance de la pièce . Achat des panneaux au coup par coup ( certes c'est moins économique ) . Mais bon , ca fonctionne . du vrai gain sur la définition , la lisibilité de la musique , la présence des instruments . Dans l évolution , ce sont les 4 panneaux arriere qui ont fait les premiers l 'effet " waouh " . Des panneaux a écouter , ils font partie intégrante de la chaine hifi

J'en suis très content, rapport qualité prix imbattable, livraison rapide, support de Andy ultra reactif, explications nombreuses, claires et détaillées, que dire de plus... Vous pouvez y aller les yeux fermés !

De qualité robuste, facile à assembler et à monter grâce aux tutos vidéo. Pas mieux sur le marché en terme de rapport qualité prix performance. Merci Andy pour les précieux conseils !

Bonjour Andy Macdoor, C'est avec plaisir que je te laisse un retour sur tes diffuseurs. Après être tombé par hasard sur tes vidéos youtube pendant mes recherches, j'ai arrêté de réfléchir. J'avais trouvé le produit qu'il me fallait ! Français, artisanale, pas cher, tout ça avec des explications et démonstrations qui permettent de nous faire savoir ce qu'on achète. La grande classe! La rapidité de traitement et d'envoi des commandes est incroyable. J'ai acheté 6 paires, je peux remplir un paquet d'espace vide avec ça. Et malgré des espaces encore libres, la faute à mon budget, ces panneaux sont très efficaces. Je garde l'air dont j'ai besoin pour l'appréciation du son, tout en réduisant les mauvaises réflexions. Je conseille à tous les musiciens et ingé son qui souhaitent traîter leurs pièces ! Un grand merci d'offrir des solutions simples, efficaces et pas chères! Alexis CUTRONE Studio Rhônin Record

En addition à divers traitements d'absorption, ces diffuseurs une fois installés au plafond dans mon cas m'ont permis d'augmenter sensiblement l'image stéréo et de la clarté sur mon écoute. En comparaison de diffuseurs plus couteux acheté chez Thom... il n'y a pas photo, c'est bien plus efficace. Je vais en reprendre pour la salle de prise son, je recommande! Merci Mr Mc door

Je suis très satisfait des diffuseurs que j'ai commandé (4 paires). Le rapport qualité-prix est imbattable, l'envoi a été rapide et les colis étaient bien emballés. Seul bémol : s'agissant de polystyrène, les diffuseurs sont très fragiles et sensibles aux chocs, chutes, griffures, etc. Il faut les manipuler avec précaution lors du montage, de la peinture et de la fixation. A part ça, ils sont super pratiques. Légers, peu onéreux et faciles à personnaliser.

La mise en collage ne pose pas de problème. Il suffit avant de commencer le collage de faire un montage à blanc, comme en menuiserie. Par contre, il est important d'éviter de les manipuler trop avant séchage complet, au risque d'une rupture du joint de colle. Cela m'est arrivé. Après avoir retiré le joint de colle, il suffit de recoller. Le temps de 48 heures de collage me parait être la bonne durée. L'aspect esthétique est bon. Par chance, la couleur est presque similaire à celle de mes murs.

J'en ai pris que 4 mais on sent le changement. Afin de vérifier ce que mes esgourdes distinguaient, j'ai fait une mesure sonarworks et effectivement c'est mieux dans les aigus. L'impression à l'écoute est : plus d'air, plus d'espace. Je recommande vivement. Un peu chiant à monter certes, j'aurai préféré un poil plus et le recevoir déjà montés tant qu'à faire. Un peu déçu par la peinture recommandée par Andy, le blanc ne fait pas blanc pétant mais plutôt ivoire. (après avoir envoyé tous les justificatifs demandés par l'entreprise en question, zéro nouvelle) mais bon rien à voir avec la qualité du produit d'Andy.

Bonjour, J'ai acheté le mois dernier 2 diffuseurs de Andy. L'assemblage est facile et rapide, petit conseil ne mettez qu'un petit filet de colle à chaque fois, moi j'en ai trop mis et les parties des diffuseurs avaient tendances à glisser l'une sur l'autre. D'abord installés entre les enceintes et l'avant du diffuseur à environ 50cms des enceintes le résultat était moyen, j'ai avancé les enceintes vers le point d'écoute et le résultat s'est amélioré. Chez moi, petit problème, les diffuseurs sont devant la télé je suis donc contraint de les enlever si je veux la regarder. Il me reste à déterminer leur hauteur pour avoir un résultat maximum et peut être en mettre deux autres à l'arrière du point d'écoute. YB

Commander après les conseils avisés de Mr Patrick Thévenot, l'acoustique de ma régie de mixage a été grandement amélioré, pour un coût vraiment dérisoire en comparaison de la qualité du résultat. Merci !!!

J'ai commandé des diffuseurs chez Andy, qui est super sympa qui m'a renseigné sur la conception et la qualité des ces diffuseurs révolutionnaires Diffuseur Acoustique MDD-400-16. Cela fait plusieurs années que je traite l'acoustique chez moi, j'ai construit une dizaine de diffuseurs en bois qui sont installés dans ma pièce dédiée, et je voulais par manque de temps compléter l'arrière de ma pièce pour corriger quelques réflexions gênantes avec ses diffuseurs. J'en ai commandé 12 pour tester que j'ai installé, et j'en suis entièrement satisfait....J'ai fais des comparaisons avec les miens en bois pour constater les différences entre bois et sagex, et bien je peux vous dire, qu'il n'y a pratiquement aucune différence et que l'apport de ces nouveaux diffuseurs ont corrigé tous les problèmes des réflexions spéculaires gênants. A recommander fortement et encore un grand merci pour ta disponibilité et tes conseils avisés.... Pascal

equivalent to a cost price of 27.50 € per diffuser

Pair of acoustic diffusers consisting of one type A diffuser and its inverse type B. These two types are mutually mirrored with respect to each other, in order to avoid problematic phase correlations that occur when two identical elements are placed in proximity.

Each diffuser is composed of 20 pre-cut lines, to be assembled by placing them next to each other.

check_circle

check_circle